Two of the 9 cardinal parameters are temperature related. In this article, the focus will be on the effect of leaf level surface temperatures (not root zone temperatures on your plants); how grow room temperatures, humidity and CO2 concentration are intimately linked to plant growth at higher temperatures; and compare the differences between ambient grow room temperatures and humidity levels in high pressure sodium (HPS) and light emitting diodes (LED) grow room temperatures and humidity levels.

Proper Grow Room Temperatures with LED Grow Lights

Leaf level temperatures are important to understand when using LED grow lights. When scientists discuss photosynthesis and temperature, they typically reference leaf temperature, not the ambient room temperature which equates to your grow room temperature. They will also discuss root zone temperatures, which we will not cover in this article. Given that the biochemistry of photosynthesis takes place inside plant’s leaves, this makes complete sense.

Cultivators that want to reap the benefits of the latest generation of LED grow lights should familiarize themselves with the nine cardinal pillars for growing plants and the relationships between environmental factors that affect plant growth and ultimate plant yields; light intensity, leaf level temperature, humidity, carbon dioxide concentration, light intensity, root zone temperature, water, nutrients and oxygen to the roots. To properly set your grow room temperatures, it is important to have sensors located within your canopy, not on the wall so that you adjust your grow room temperatures accurately.

Unlike plant scientists, when mechanical engineers discuss temperature, they usually reference the ambient grow room temperature. In growing environments with high-pressure sodium (HPS) lights, the leaf temperature will be higher than the ambient grow room air temperature surrounding the plant. High-pressure sodium (HPS) lights, which emit infrared radiation that is absorbed as heat by the plant. As well HPS bulbs concentrate and retain heat.

HPS bulbs emit a large infrared peak between 800nm and 900nm. This infrared peak significantly increases leaf temperatures at the top of the canopy, where most of the infrared light is absorbed. When examining the differences between leaf temperatures of plants grown in the same room under either HPS or LED lights, we will see significant temperature differences that infrared light causes.

In a study done by scientists, they measured the photosynthetic activity and internal leaf temperature of leaves at different distances from the light source. The internal leaf temperature measurements were very clear. The leaves of plants under LEDs did not show an increase for internal leaf temperature significantly above the ambient room temp at any distance between 2’ and 4’ from the lamp. In contrast, the leaves of plants under the HPS lamps showed a wide range of internal temperatures; the highest temps were apparent at the top of the canopy and lowest internal leaf temperatures were at the bottom of the canopy.

To maintain optimized leaf level surface temperatures in a room with LED grow light fixtures, you must increase the overall ambient grow room temperature. Cannabis plants thrive at 82°F to 84°F leaf surface temperatures (LST). With LED lights, and because no radiant heat is cast directly below the fixture, it is best to keep your ambient grow room temperatures at 82°F to 84°F. This will maintain your top canopy yields while maintaining and increasing lower-level canopy yields.

Based on scientific study and experimentation cultivators found that an increase in the ambient grow room temperature of 5-7°F in LED-lit rooms relative to temperatures in HPS grow rooms is necessary to achieve similar internal leaf temperatures and plant growth rates equal to or greater than those experienced by plants in HPS-lit rooms.

LST plays a pivotal role in overall plant health. Many metabolic processes within the plant structure are optimized with the proper temperature. If the temperature is not kept consistent for maximizing vapor pressure deficit (VPD), your ultimate yields will be less. If temperatures dip or spike dramatically, growers may witness inhibited growth, plant stress or irreversible damage to their crops. Many strains react to stress by turning into a hermaphrodite!

Vapor Pressure Deficit (VPD) and LST

Keep in mind that as the ambient grow room temperature increases, the relative humidity decreases, and proportionate adjustments should be made to the relative humidity to adjust VPD.

Leading plant scientist Dr. Eric Runkle of Michigan State University states in an article on VPD:

“Vapor-pressure deficit (VPD) is independent of temperature and is a more accurate measure to predict plant transpiration and water loss than relative humidity.

Relative humidity (RH) refers to the amount of water vapor in the air versus what it can hold. The amount of water that air can hold varies with temperature; warmer air has a greater water-holding capacity than cooler air. The water-holding capacity of air approximately doubles with every 20°F increase in temperature. Consequently, air that is at 80°F can hold twice the amount of water compared with 60°F. Instead of relative humidity,the more accurate way to express the driving force of water loss from a leaf is vapor pressure deficit (VPD).Its value is independent of temperature. VPD is the difference between the amount of moisture in the air and how much moisture the air could potentially hold when it’s saturated”

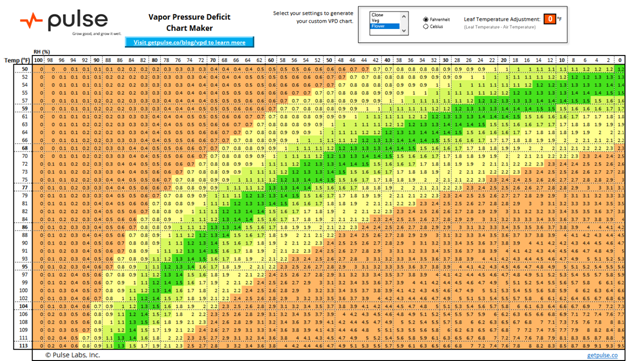

The chart on best temperature and RH levels is from VPD charting software from Pulse. You can gain more insight into VPD by visiting their site at www.pulsegrow.com. This chart is for your flowering room, you can get the chart maker and VPD monitors on the Pulse website for all your cultivation rooms.

Address Possible Humidity Problems Early

When the temperature drops at “night,” the relative humidity changes. The amount of water in the air remains the same when the lights go out, but the RH goes up. Relative to warmer air, the now-cooler air is beginning to max out its capacity to carry water. And because the air can’t so easily hold it—and because the surfaces of the plants are cooling too—condensation begins to build. Just like a pint of beer on a hot day the plants become covered in water droplets and dew. This is especially bad in the large-surface-area of the buds with all their nooks and crannies. And where there’s moisture, mold isn’t far behind.

Plants, just like humans, can’t easily cool themselves when it’s humid. Transpiration isn’t as effective because the water won’t evaporate as easily. And with nowhere to release the water, the plants stop taking it in from the roots. That not only means they’ve stopped “drinking,” but that they’ve stopped “eating” too. With no nutrient intake, growth slows.

Then, the more dangerous side of the humidity problem comes into play. Mold spores, which are present on all surfaces everywhere around us, find the conditions they need to propagate. With a little extra moisture and warmth, grey mold and powdery mildew take hold and, once they do, there’s not much to be done. Bud rot ensues. Remediation techniques exist, but in all likelihood, a mold outbreak results in crop loss.

Managing your humidity levels start with proper design and mechanical engineering and design based upon your sensible and latent loads that must be calculated before you start growing.

Grow Room Temperature And CO2 for Photosynthesis

Enzyme ribulose 1,5-bisphosphate carboxylase (RuBisCO) is an enzyme present in plant chloroplasts, involved in fixing atmospheric carbon dioxide during photosynthesis and in oxygenation of the resulting compound during photorespiration. This chemical reaction is seen as the conversion of CO2 and water into simple sugars during photosynthesis. The chemical reaction that RuBisCO performs is highly dependent upon temperature, light and the atmospheric C02.

Under sunlight and ambient CO2 concentrations of about 300ppm, as well as a temperature range of 41°F and 81°F, the rate at which CO2 is absorbed by the plant and converted to sucrose increases as the temperature increases, leading to increasing gains in net photosynthesis.Typically commercial cultivation will increase CO2 concentrations to as high as 1500ppm.

An indoor grower in a fully controlled and enclosed environment can adjust their environment to achieve optimal growing conditions much better than someone growing in an enclosed greenhouse environment. Controlled indoor environments allow growers to maintain optimal grow room temperatures, carbon dioxide concentrations, light intensity and relative humidity. The grower can adjust the cultivation environment to take advantage of high rates of growth that occur at high temperatures, elevated PPFD lighting levels, and additional CO2 concentrations.

Increasing CO2 concentrations and elevated PPFD levels will expand the grow room temperature range in which RuBisCO may fix CO2 into sugar. With expanded CO2 concentrations and grow room temperature increases, the rate of the chemical reaction that RuBisCOcorrespondingly increases. Cultivators may achieve very high rates of carbon fixation and plant growth at leaf temperatures well above 86°F.The results are increased yields, flavor, terpenes and cannabinoids. Since the rate of carbon fixation by RuBisCO is affected by leaf temperature and CO2 concentration, increasing the ambient temperature in LED-lit rooms will increase the rate of photosynthesis and plant growth.

Randy Shipley is a co-founder and the President of RSX Enterprises and is responsible for sales, marketing, product development and technology. He also leads RSX’s design, build and facility start-up advisory services team, with a focus on assisting cultivators with facility and floor plan design assistance for lighting, benching, HVACD and other critical growing systems. Connect with Randy on LinkedIn