Why Do Cannabis Cultivation Facilities Struggle with HVAC and Dehumidification Planning?

Many cannabis cultivation facilities face significant challenges in designing and implementing effective HVAC and dehumidification systems. These difficulties arise from underestimating moisture loads, improper equipment sizing, lack of industry standards, and cost-cutting measures. Understanding the science behind environmental control and selecting the right equipment is crucial to maintaining optimal growing conditions, ensuring plant health, and maximizing yield.

Understanding MBH and Its Role in Cannabis Cultivation HVAC Design

Latent vs. Sensible Loads in MBH Calculations

When calculating MBH for cannabis cultivation HVAC systems, it is essential to distinguish between latent and sensible heat loads:

- Sensible Load: The portion of heat that directly affects air temperature. This includes heat from lights, equipment, and external sources.

- Latent Load: The portion of heat associated with moisture in the air. This includes water vapor from plant transpiration and irrigation, which contributes to humidity levels.

Since dehumidification requires energy to remove moisture from the air, both sensible and latent loads must be factored into HVAC system design. Neglecting latent loads can result in inadequate dehumidification, excessive humidity levels, mold growth, and plant stress.

MBH stands for “thousands of BTUs per hour” (where M represents 1,000 in Roman numerals). It is a standard unit of measurement used to express the heating or cooling capacity of HVAC equipment.

- 1 MBH = 1,000 BTUs per hour (BTU/h)

- MBH is critical in determining the cooling load needed to offset heat from lighting, equipment, and plant transpiration in a grow room.

Improper MBH calculations can lead to undersized HVAC systems, resulting in excessive humidity, poor air circulation, and inefficient energy use in cannabis cultivation.

How to Calculate Pounds of Water Per Hour (lb/hr) for Dehumidification

A major factor in HVAC and dehumidification planning is understanding how much moisture cannabis plants release into the air. The amount of water vapor that must be removed is calculated as follows:

- Estimate Plant Transpiration Rates

- A growing cannabis plant emits somewhere between 95-99% of the water that it takes in during its transpiration process. When this happens, the moisture extends back into the room where the plant is growing. Because of the high transpiration rate in cannabis, it’s critical to monitor the VPD on a regular basis.

- Example: If a grow room irrigates 100 gallons per day, approximately 95-99 `gallons will be transpired into the air.

- 1 gallon of water = 8.34 lbs, so 95 gallons ≈ 792 lbs of water per day.

- Convert to Hourly Moisture Load

- Divide daily moisture load by 24 hours:

- 792 lbs/day ÷ 24 hours = 33 lb/hr

- This means the dehumidification system must remove 33 lbs of water per hour to maintain optimal humidity levels in a cannabis cultivation facility.

- Divide daily moisture load by 24 hours:

- Adjust for Additional Moisture Sources

- Factors like people, irrigation runoff, and HVAC latent heat loads can increase the required moisture removal.

- Safety margins should be added to accommodate fluctuations in humidity levels.

- Match Dehumidification Equipment Capacity

- Dehumidifiers and HVAC systems are rated in pints per day (PPD) or lbs per hour.

- 1 pint = 1.043 lbs of water, so converting required lb/hr helps select the right equipment.

How Air Temperature Affects Moisture Removal in Cannabis Cultivation

Air temperature plays a critical role in determining how efficiently HVAC and dehumidification systems remove moisture. Understanding this relationship helps prevent mold, plant stress, and inefficiencies.

- Warmer Air Holds More Moisture

- Higher temperatures allow air to retain more water vapor before reaching saturation.

- Example:

- At 70°F, air can hold about 8 grains of moisture per cubic foot.

- At 85°F, air can hold over 15 grains—almost double the moisture.

- This means that at higher temperatures, more dehumidification capacity is needed to maintain the same relative humidity (RH) in a cannabis grow room.

- Warmer Conditions Improve Moisture Removal Efficiency

- Dehumidifiers work by condensing moisture from the air, and efficiency improves when:

- The air temperature is higher than the coil temperature.

- Warmer air holds more moisture, meaning more condensation occurs on cold coils.

- Properly designed HVAC and dehumidification systems can optimize moisture removal by maintaining ideal temperature ranges.

- Hor Gas Reheat For Dehumidification

Hot Gas Reheat (HGRH) is a highly efficient method used in HVAC systems to dehumidify air without overcooling a space. It works by redirecting excess heat from the refrigerant cycle to reheat dehumidified air before reintroducing it into the grow room.

How It Works:

-

The HVAC system cools the air to remove moisture through condensation.

-

Instead of expelling waste heat, hot gas from the compressor is used to reheat the air before it is distributed back into the room.

-

This process allows for precise humidity control while maintaining a stable temperature.

Efficiency Benefits:

-

Reduces energy consumption by repurposing waste heat.

-

Prevents overcooling, which can stress plants and disrupt VPD balance.

-

Provides a cost-effective alternative to electric or hydronic reheat solutions.

-

Helps maintain consistent temperature and humidity for optimal cannabis cultivation conditions.

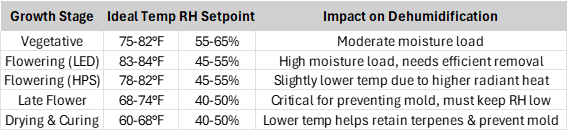

- Ideal Temperature Ranges for Cannabis Cultivation Dehumidification

*It is important to maintain a leaf surface temperature of 83°F until Late Flower.

Additionally, during Late Flower and Drying, desiccant dehumidifiers may be recommended to handle peak dehumidification loads effectively. These systems can remove moisture even at lower temperatures, ensuring precise humidity control without excessive cooling.

Understanding Vapor Pressure Deficit (VPD)

The ideal temperature ranges listed above allow growers to dial in Vapor Pressure Deficit (VPD) to desired levels. VPD is a crucial metric in cannabis cultivation that measures the difference between the amount of moisture in the air and the maximum amount the air can hold at a given temperature. Proper VPD control ensures optimal transpiration rates, nutrient uptake, and overall plant health. By adjusting temperature and humidity to target the correct VPD range, growers can maximize growth efficiency, reduce disease risk, and fine-tune environmental conditions to achieve higher yields and quality.

What is a Desiccant Dehumidifier?

A desiccant dehumidifier removes moisture from the air using a desiccant material, such as silica gel, that absorbs water vapor. Unlike refrigerant-based dehumidifiers that rely on cooling coils to condense moisture, desiccant dehumidifiers function efficiently in low-temperature and low-humidity conditions, making them ideal for late flowering and drying rooms in cannabis cultivation. They provide consistent humidity control, prevent mold formation, and help preserve the quality of harvested cannabis by maintaining stable drying conditions.

Key Takeaways:

- Higher temperatures = More moisture to remove, but better HVAC efficiency.

- Lower temperatures = Less moisture, but potential coil freezing & inefficiencies.

- Desiccant dehumidifiers may be beneficial for Late Flower and Drying phases.

- Balancing temperature & RH optimizes plant health and HVAC performance in cannabis cultivation.